How do factories deshell pumpkin seeds?

SynopsisFactories can deshell pumpkin seeds using various methods

Factories can deshell pumpkin seeds using various methods, including:

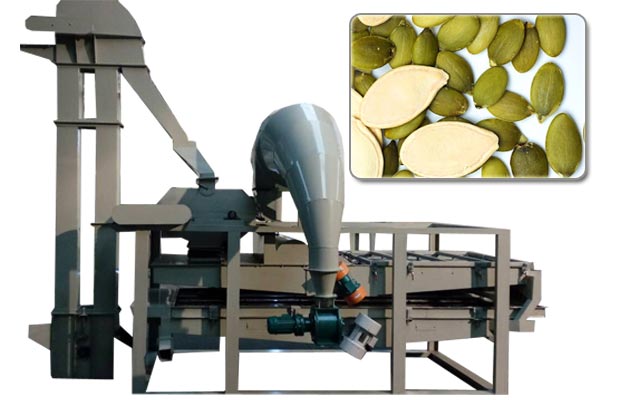

1. Mechanical Dehulling: In this process, machines use friction, pressure, or abrasion to remove the outer shell of the pumpkin seed. The seeds are fed into a revolving drum or a roller mill that cracks the outer shell, allowing the kernel to separate from the shell.

2. Wet Dehulling: This method involves soaking the pumpkin seeds in water for a specific period before the hull is removed. This process loosens the hull from the kernel, making them easier to remove.

3. Dry Dehulling: This method involves roasting the pumpkin seeds before the shell is removed. Roasting the seeds heats up the hull, making it more fragile and easier to remove.

4. Combination Method: This method involves a combination of mechanical and heat dehulling. In this approach, the pumpkin seeds are first roasted, and then a machine is used to remove the shell.

After the dehulling process, the pumpkin seeds are usually separated from the hulls using a blower or a separator. Finally, the seeds are cleaned and packed for distribution or further processing.

Leave a reply