Product Information

The WINTONE kiln is used for heat treatment of cereals, mainly oats.

Inactivates enzymes to create uniform, premium products

The kiln inactivates enzymes in the kernels, improving digestibility and creating a nutty taste. This prevents the finished product from becoming rancid. The kiln also treats the product evenly, by alternately charging the radiators in the heating compartments with vapor.

The respective product enters the kiln via the upstream pre-bin with the subsequent steamer. The steamer causes an increase in temperature and moisture via a direct addition of steam. After the direct addition of steam, the product reaches several shaft-shaped compartments arranged one above the other. Depending on the required capacity and temperature, the kiln can consist of 1-5 heating compartments.

Advantages of the kiln:

Increase of the product shelf life and improvement of the taste

Improved adjustability of the heating and cooling times

A specially designed discharge hopper ensures mass flow during product discharge.

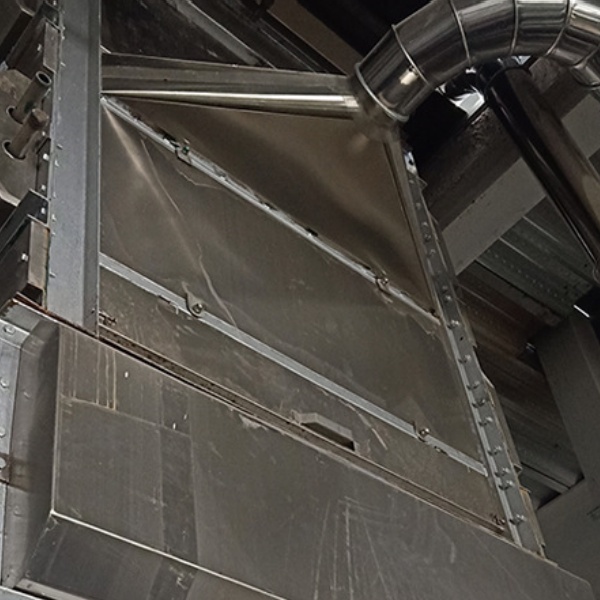

Designed for easy maintenance and cleaning: You can easily remove all air, vapor and condensed water lines. You can pull out the stainless steel radiators. There are also hinged cleaning flaps with quick closures in the cooling compartment's air outlet hoods.

Designed for 24/7 operation: The kiln is sturdy, designed for safe and continuous operation even under demanding production conditions.